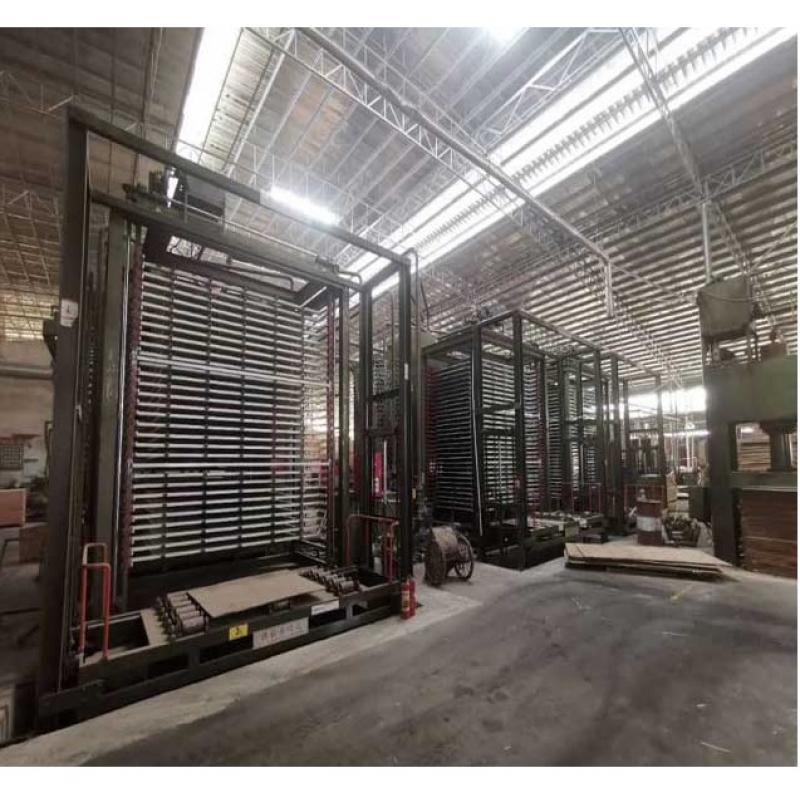

Layer Hot Press Machine-manufacture,factory,supplier from China

(Total 24 Products for Layer Hot Press Machine)

Hydraulic Hot Roller Press MachinePlywood hot press machine is used for the final formulation of plywood, it is the most important machine in plywood production. Hot press machine is one of the most important machines in plywood production.

Contact Now

Woodworking Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood, it is the most important machine in plywood production. Hot press machine is one of the most important machines in plywood production.

Contact Now

Hydraulic Veneer Hot Press Machine For PlywoodHot press machine is one of the most important machines in plywood production. It determines production efficiency and the quality of final products.

Contact Now

Automatic Hot Roller Press Machine For LaminatesPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

15 Layers Industrial Wood Machine Hot Press MachinePlywood hot press system can press veneers together with excessive temperature.that's used in furniture and synthetic board secondary operation. guide and automated controls make the hydraulic press quicker, greater precise, and greater convenient for global customers to apply.our warm press is ready with a microcomputer manage device for each guide and automated manipulate.

Contact Now

Plywood Hydraulic Hot Press Machinery Plywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Wood Laminate Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood,it's most the maximum critical machine in plywood production.hot press machine is one of the maximum important machines in plywood production.it determines production efficiency and the nice of final merchandise.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts.extensive range of procedure parameters adjustment control system,affordable design to fulfill diverse pl

Contact Now

Multi Layer Converyor Mesh Belt DryerkiMesh belt dryer is a closed-belt dryer. Its feature is that only the feed end and the discharge end are open, and the others are closed.

Contact Now

Wood Laminate Veneer Hot Press MachinePlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation.Manual and automatic controls make the hydraulic press faster,more precise,and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.With a simple push of a button you can control a whole set of processes including pressing plate ascending,closing, pressure adding, pressure maintaining,timing and pressing plate descendin

Contact Now

Multilayers Hot Press Wood MachinePlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requir

Contact Now

Hot Pressing Laminating Press Machine For WoodPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Automatic Hot Press Woodworking Machine for VeneerPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Wood Laminate Hot Press Woodworking MachinePlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Roller Veneer Hot Press Dryer MachineRoller Veneer Drying Machine is available in different models as per the production requirement by addition & deduction of different section or decks. The wood core veneer dryer machine adopts a number of high-tech and advanced electronic control technology, so it has the characteristics of high efficiency, energy saving and good dry quality. Veneer drying machine is suitable for peeling core of drying.

Contact Now

Wood Plywood Cold Press MachineThe hydraulic press applied to plywood is also called plywood pre-press and plywood cold press. The cold press is also a kind of plywood machine. It is mechanical equipment to shorten the hot pressing cycle and improve the quality of the board. The cold press is a pressure machine. The cold press machine mainly performs a short-time cold press on the veneer after the glue-coated assembly blank, so that it is initially formed, and then sent to the hot press for the process of hot pressing and gluing.

Contact Now

Industrial Hot Press Machine ProductsPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation.Manual and automatic controls make the hydraulic press faster,more precise,and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.With a simple push of a button you can control a whole set of processes including pressing plate ascending,closing,pressure adding,pressure maintaining,timing and pressing plate descending.&

Contact Now

Woodworking Hot Press Machine For VeneerOur Hot press machine low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requirements. Product parametersTotal pressure500tonsBoard feeding directionFrom the long sidePressure0-25mpaHot Press Plate Size2700*1370*40mm double inlet and outletCylinder diameter and strokeΦ360x2, 1050mmFrameBolt connectedLayer number15 layersLayer space70mmhot press plate number16total power20.5kw

Contact Now

Hydraulic Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process r

Contact Now

Wood Hot Press Machinery PlywoodHot press machine is one of the most important machines in plywood production. It determines production efficiency and the quality of final products.

Contact Now

Laminate Hot Press Veneer Machine For WoodPlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production proces

Contact Now

Continuous Veneer Hot Press Dryer EmissionsVeneer dryer Machine is one of important auxiliary equipments in large-scale plywood production line, and help you to improve productivity and reduce cost.The moisture in the veneer affects the total drying time. For example, the difference in moisture content of the heartwood of redwood from different logs may be as much as 2 to 1. The wetter heartwood veneer requires significantly longer drying time than drier heartwood of the same species.

Contact Now

Plywood Wood Cold Press Laminate MachineThe cold press is also a kind of plywood machine. It is mechanical equipment to shorten the hot pressing cycle and improve the quality of the board. The cold press is a pressure machine. The cold press machine mainly performs a short-time cold press on the veneer after the glue-coated assembly blank, so that it is initially formed, and then sent to the hot press for the process of hot pressing and gluing. It is an important piece of equipment to improve the quality of plywood, and it is also an mportant link.

Contact Now

Single Layer Continous Mesh Belt DryerMesh belt veneer dryer that's one of the primary gadget in veneer and plywood production and can be used for continuous drying operation. it is used for drying veneers with rotary cutting and slicer and it is designed specially to dry the very thin face veneer usually at 0.2-1.2mm thickness. it is composed of four components, which can be divided into feeding area, heating location, cooling area and discharging place.

Contact Now

Wood Laminate Veneer Hot Press MachinePlywood Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system, heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requirements. Product parametersTotal pressure500tonsBoard feeding directionFrom the long sidePressure0-25mpaHot P

Contact Now

Relate News

We are pleased to announce that the double-layer veneer dryer recently customized for a Thai customer has been completed and is being prepared for shipment.

The third set of new 4-layer 38-meter veneer dryer purchased by Chongzuo customers has been installed and is in normal use. Thank you for your recognition of our equipment.

The 36-meter double-layer veneer dryer purchased by xishuangbanna customers has been installed and successfully run. In addition, a drying room is added. It uses biomass burner to burn waste wood for heating, which greatly saves the drying cost and produces uniform moisture content of veneer.

The 38-meter four-layer veneer dryer purchased by Guangdong customers has been successfully installed and run. It uses biomass burner to burn waste wood for heating and has the function of automatic stacking, which greatly saves labor costs.

Vietnamese customer's 40-meter single-layer veneer drying equipment is being installed. Due to the impact of the epidemic, the engineer cannot go to the site to install it. We will guide the customer to complete the installation smoothly through the video.

Veneer dryers are mainly used in the veneer processing industry. Its purpose is to improve the stability and quality of veneers by removing moisture from the veneers, so that they are more suitable for subsequent processing and use. There are mainly the following common types of veneer dryers:Roller veneer dryersuitable for drying core boards. The veneers after drying have good flatness, uniform moisture content, and good surface bonding. Its working principle is to heat and dry the veneers with hot air. The hot air is generated by the combustion furnace and blown to the veneers by the fan.

Due to various reasons, our engineers were unable to install it on site. This 32-meter double-layer veneer dryer was installed by our Russian customers under our guidance.

Cambodian customers previously purchased two sets of our 56-meter double-layer dryers for drying rubber wood.The maximum output can reach 120 cubic meters a day.The customer feedback is very good, and they recognize our equipment.We must maintain and strive to do better,and welcome to visit our factory at any time.

This is our old customers in South Africa after purchasing the second double equipment purchased from us before users a double veneer dryer equipment, production from the use of machines and production experience after feeling is very good, and easy to operate, by our engineer to assist installation and guidance, have what problem can be solved on the spot, to avoid the trouble back at home, After a period of time, the customer will purchase the second device from us again. We are very grateful for the support of the South African users and hope to get more support.

Industrial knife grinding machine can automatically adjust the grinding parameters according to the material and shape of different knives, and accurately complete the grinding, repair and maintenance of knives.Industrial knife grinding machine are suitable for grinding all kinds of knives, including but not limited to cutting knives, trimming knives, scrapers, milling cutters, turning tools, etc. Whether it is precision cutting, complex-shaped knives, or large-scale tool repairs, knife sharpeners can complete them accurately and quickly.